Manufacturers and testing services use coordinate measuring machines, or CMMs, to inspect the dimensional quality and characteristics of manufactured goods to ensure they meet design requirements. CMM inspections, offered by Coweta Tech Precision, use these machines to measure parts or the entirety of a three-dimensional object and compare those measurements against the design file's specifications. They measure objects along the X, Y, and Z axes to provide a three-dimensional assessment of the product.

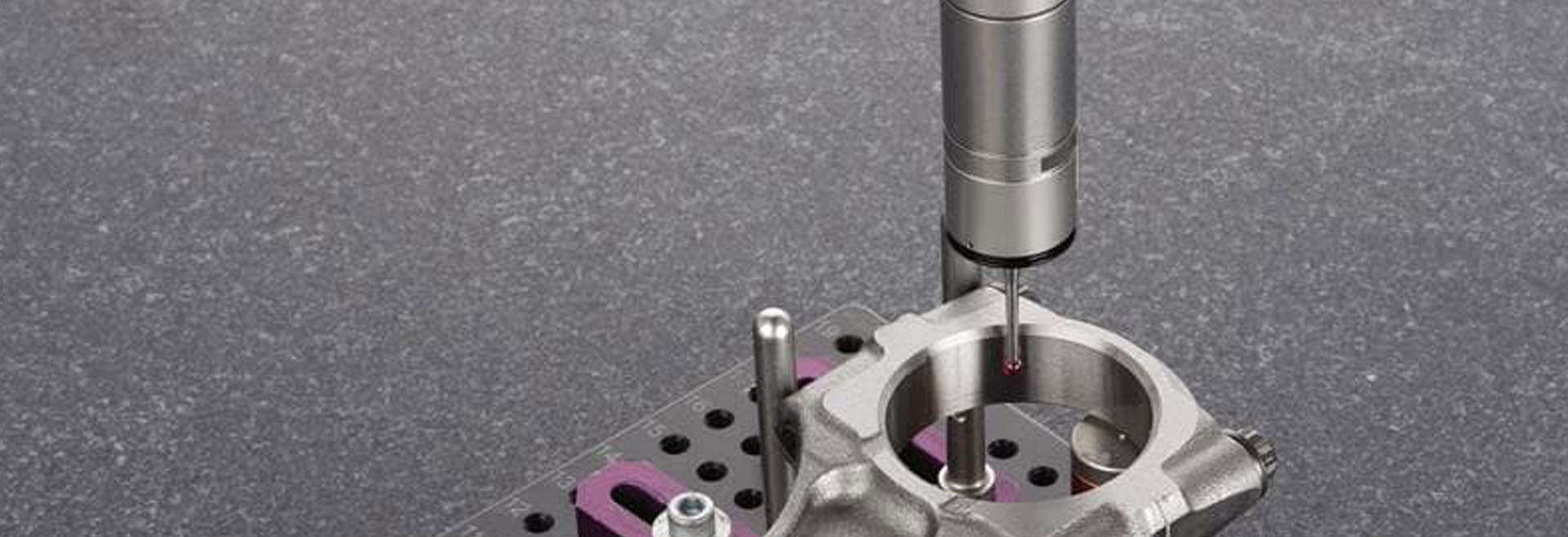

CMMs work by having a probe that moves along the surface of a product or uses sensors to indirectly measure surface qualities. Along with its probe, each machine has a base or bed that holds the product and a computer that both directs the probe and gathers the resulting measurement data.

Because CMMs can measure components along all three axes, the machines can collect a lot of in-depth data about the item. The probe offers very sensitive readings because the CMM's attached computer notes the exact position of the probe against a product's surface, allowing it to map the measured object's orientation, size, features, and position. Some of the different types of measurements it can take include the following:

Capability Maturity Models (CMMs) are another process that prioritizes standardization and in-depth quality control. These models establish five levels of capability against which different individuals, teams, or work processes can be assessed. It operates as an indirect or comparative analysis tool for marketing strengths and room for improvement. The five levels of capability maturity models are:

CMM inspections are valuable throughout the manufacturing sector. As parts and assemblies become more complex, more specialized, and more efficient, manufacturers need tight quality control processes to ensure that parts fit the parameters of the original design project. So CMMs are used to inspect geometrically complex goods, molded or machined parts, electronic assemblies, and more. With advanced CMMs, manufacturers can measure everything from the dimensions to the smoothness of the surface finish to ensure quality compliance.

We offer advanced CNC machining services and CMM Inspections for the aerospace industry, ensuring high-quality, precision-engineered parts that comply with stringent safety and quality standards. These parts are vital for reliable aerospace operations. CMM inspections are frequently used for:

Automotive manufacturers use CMM inspections to assess the dimensional requirements of the following parts within accepted tolerances:

Coweta Tech Precision specializes in CNC machining for the medical industry, creating high-precision parts for devices like implants and pacemakers. Their meticulous process ensures quality and reliability for essential healthcare components. Manufacturers use CMM inspections to confirm the quality of essential products such as stents, pacemakers, and artificial joints.

Coweta Tech Precision specializes in CNC precision machining for military and defense, ensuring that aircraft engine parts, weaponry components, and missile parts meet stringent standards. Their use of coordinate measuring machines (CMMs) guarantees precision in crafting components with tight tolerances vital for various military applications, enhancing safety and effectiveness. This meticulous process underscores their commitment to quality and reliability in demanding defense environments.

CMM inspections are used to assess microchips, electric connectors, and printed circuit board configurations.

Molds are tested to ensure they maintain all necessary design considerations.

CMMs can measure tools and dies across every dimension before production begins.

CMM inspections are vital for ensuring the high-quality production of turbines, generator components, and power transmission systems.

Optimize your quality assurance processes with CMM inspection services from Coweta Precision Tech. We serve local manufacturers with complete CMM inspection options that align with industry standards and best practices. Contact us today to get started.

Copyright © 2024 Coweta Tech Precision.