Providing High-Quality Precision Machining and CNC Machining Services in Georgia For Over 25 Years.

CNC (Computerized Numerical Control) Machining is where a computer controls the movement of the machine axes. As a result, manufactures could bring their product to market much faster.

Prior to the invention of CNC, a human operator, using complex math, would manually machine parts using a knee mill or other hand tools. Furthermore, the process was exhausting and lead to high cost and delivery due to the time it would take to do the math and manually move axes by hand.

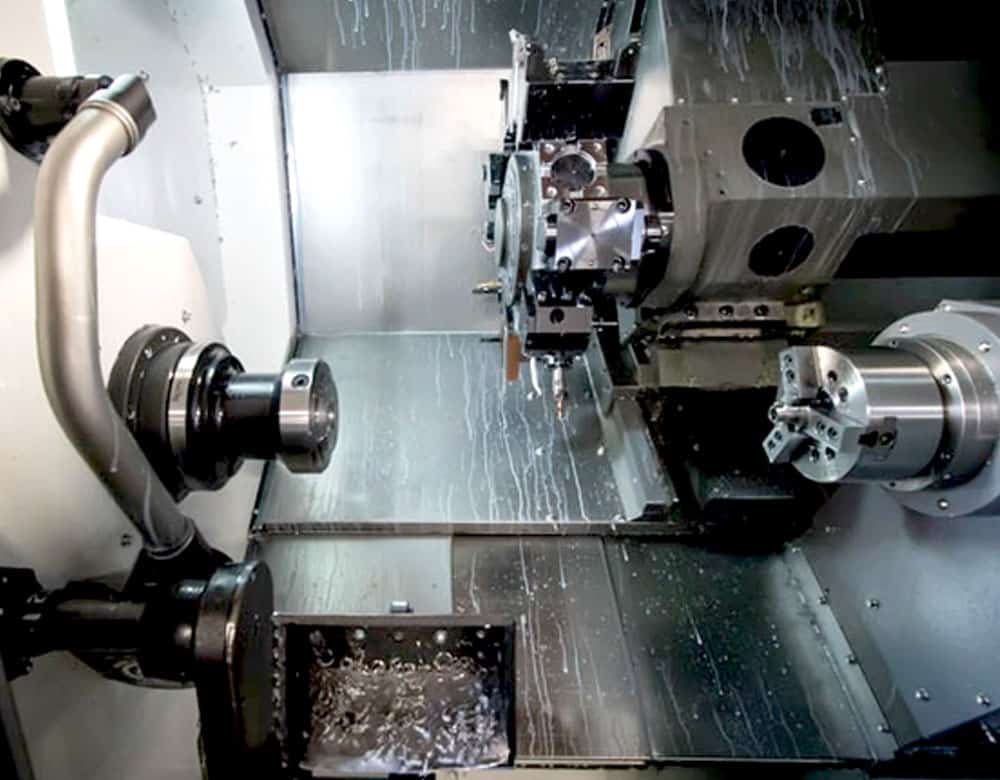

Turning is a slightly different process compared to CNC milling. CNC turning relies upon computer-controlled machines, but creates a different end product. The process uses a single-point cutting tool that is inserted parallel to the material that will be cut. The material ( metal, plastic, etc.) is rotated at varying speeds and the cutting tool traverses the 2 axis of motion to produce cylindrical cuts with exact depths and diameters.

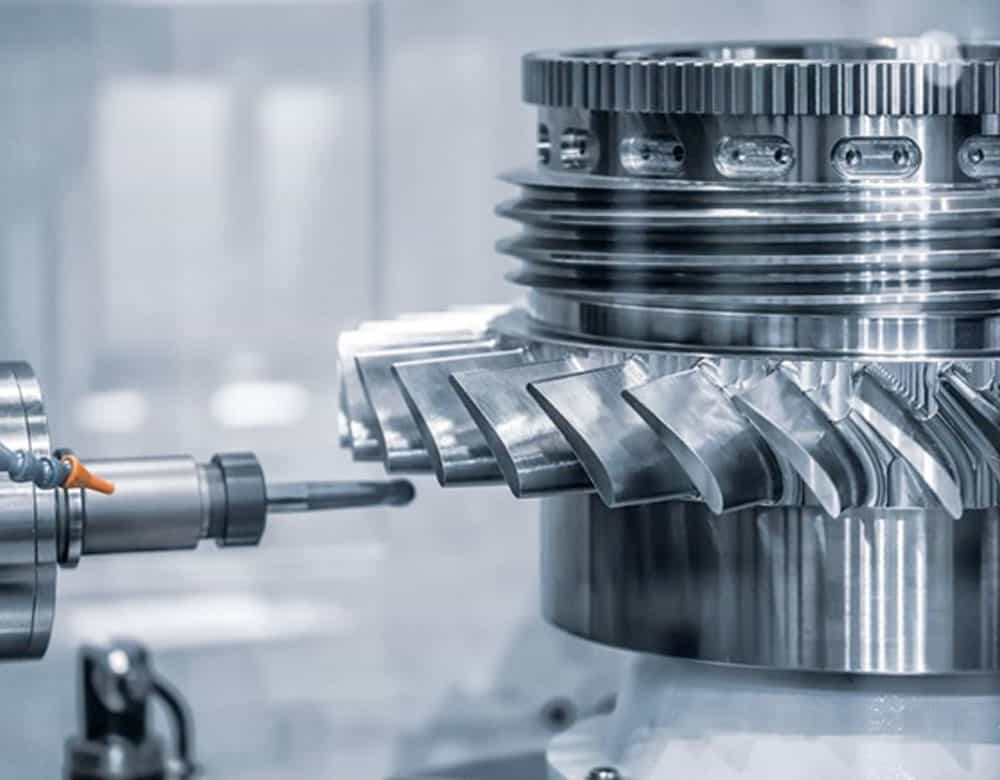

Milling is the machining process of using rotary cutters to remove material [1] from a workpiece by advancing (or feeding) in a direction at an angle with the axis of the tool. [2][3] It covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes in industry and machine shops today for machining parts to precise sizes and shapes.

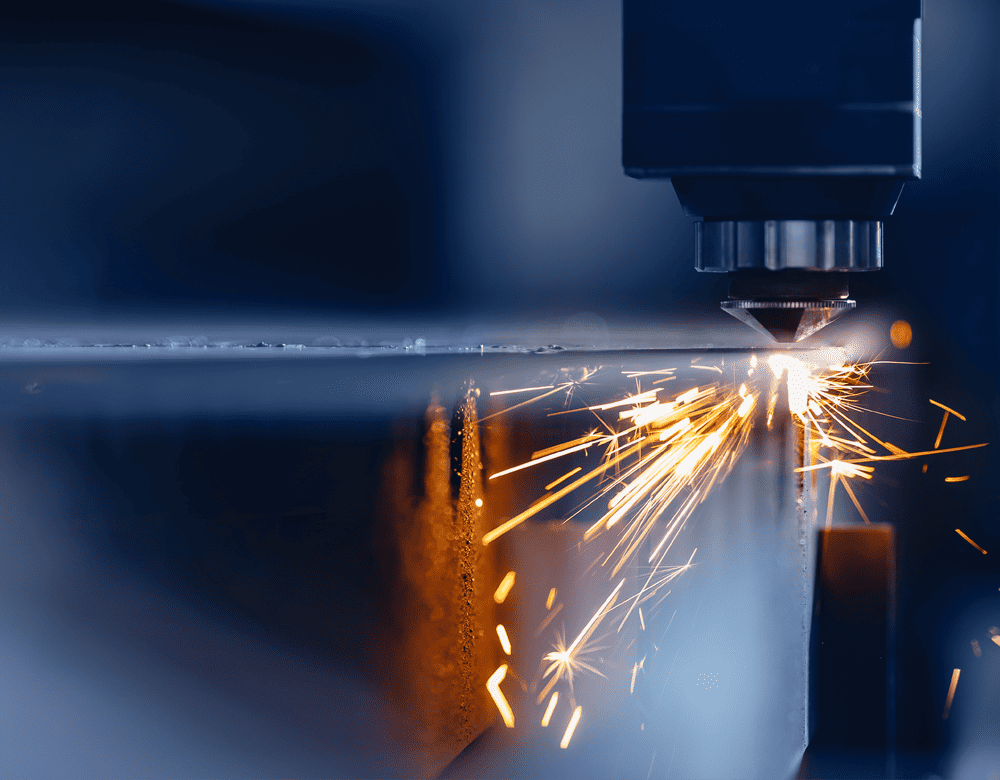

Useful for industries ranging from automotive and aerospace to electronics and healthcare, laser engraving is a subtractive manufacturing technique that removes precise material amounts from a workpiece's surface to achieve a custom design. The process uses computer-controlled beams of high-heat light and a series of mirrors to permanently and safely burn words, part numbers, logos, and more into a component. Applicable for metal, plastic, wood, glass, stone, ceramic, and leather, laser engraving offers a versatile opportunity for displaying branding or relevant product information.

Copyright © 2024 Coweta Tech Precision.